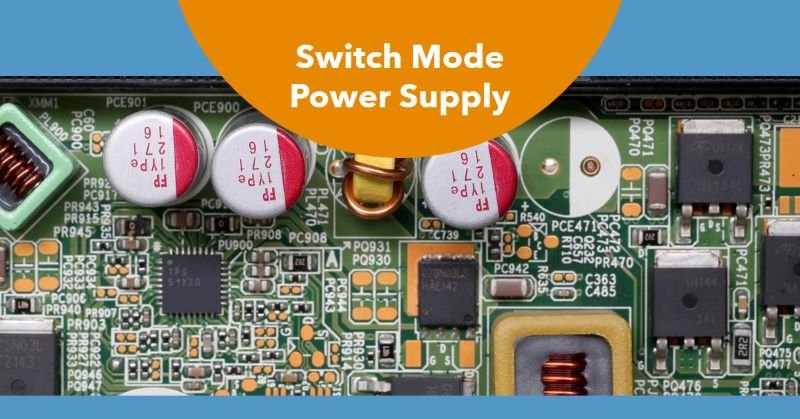

Switch Mode Power Supply(SMPS): Block Diagram, Working and Applications

A Switch Mode Power Supply (SMPS) is a highly efficient power supply unit that uses high-frequency switching techniques to convert electrical power. It’s widely used in modern electronics due to its ability to provide stable, regulated output voltage while minimizing heat generation and energy loss. SMPS operates by switching the input power on and off rapidly, then controlling the amount of energy sent to the load using a feedback loop.

SMPS has become essential in a variety of applications due to its compact size, efficiency, and flexibility. It’s found in consumer electronics like computers, televisions, and mobile chargers, as well as in industrial equipment and telecommunications systems. The ability of SMPS to handle a wide range of input voltages and deliver different output voltages makes it ideal for use in devices that require precise power regulation.

Comparison with Traditional Power Supplies (Linear vs SMPS)

Compared to traditional linear power supplies, SMPS offers several advantages. Linear power supplies regulate voltage by dissipating excess energy as heat, leading to inefficiencies, especially at higher power levels. SMPS, on the other hand, uses switching techniques that are much more energy-efficient. Additionally, SMPS is typically smaller and lighter than linear power supplies, making it more suitable for portable and space-constrained applications. However, SMPS designs are more complex and can generate electromagnetic interference (EMI), which requires additional filtering.

What is SMPS?

A Switch Mode Power Supply (SMPS) is a type of power supply that converts electrical power efficiently by using switching regulators and pulse-width modulation (PWM). It takes power from an AC or DC source and converts it into regulated DC output. The key feature of SMPS is its ability to switch the power flow on and off at high frequencies, reducing energy losses and improving efficiency.

The SMPS are mainly comes in four types are as follows:

- AC-DC SMPS

- DC-DC SMPS

- Flyback Converter

- Forward Converter

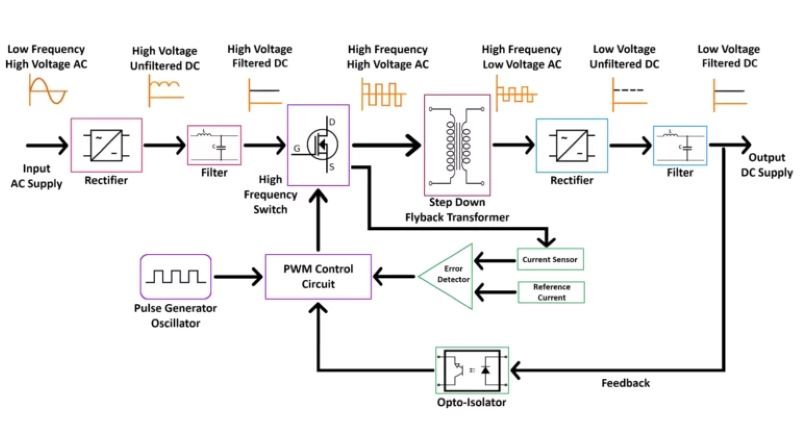

SMPS Block Diagram

The block diagram of an SMPS consists of several key components that work together to convert electrical power efficiently.

Input Filter

The input filter is the first stage in the SMPS and is responsible for removing unwanted noise and harmonics from the input power source. This stage also helps to prevent electromagnetic interference (EMI) generated by the switching components from affecting the power supply.

Rectifier

The rectifier converts the incoming AC voltage to DC. In an AC-DC SMPS, this is done using a diode bridge that allows current to flow in one direction, ensuring that the output is a pulsating DC voltage, which is then smoothed using capacitors.

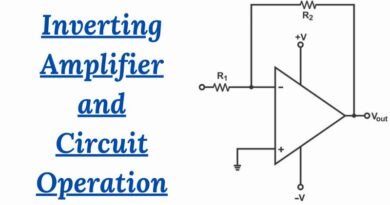

Switching Element (Transistor/MOSFET)

The switching element is the heart of the SMPS. It rapidly turns on and off at high frequencies, controlling the power flow to the transformer or inductor. Commonly used components include MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) due to their fast switching speeds and high efficiency.

PWM Controller

The Pulse Width Modulation (PWM) controller is responsible for adjusting the duty cycle of the switching element to regulate the output voltage. By controlling the amount of time the switch is on versus off, the PWM controller ensures that the output voltage stays constant even when input voltage or load conditions change.

Transformer

The transformer in SMPS operates at high frequencies and is responsible for stepping the voltage up or down depending on the design requirements. In addition to voltage conversion, the transformer provides isolation between the input and output, which is critical for safety in many applications.

Output Rectifier and Filter

Once the voltage has been stepped down or up by the transformer, it is rectified again using fast diodes to convert the high-frequency AC back to DC. The output filter, typically consisting of capacitors and inductors, smooths the rectified DC to provide a clean, stable output voltage to the load.

Feedback Control Circuit

The feedback circuit constantly monitors the output voltage and provides feedback to the PWM controller to adjust the duty cycle as needed. This ensures that the output remains stable even under varying load conditions. The feedback circuit usually includes a reference voltage, error amplifier, and optocoupler for isolated feedback.

Working of SMPS

Step-by-Step Working Process of SMPS

- AC to DC Conversion: The SMPS starts by converting AC input into a DC voltage using a rectifier and smoothing filter.

- High-Frequency Switching: The DC voltage is then chopped into a high-frequency AC signal using a switching element (such as a MOSFET) controlled by a PWM controller.

- Voltage Conversion via Transformer: This high-frequency AC signal is sent through a transformer to either step up or step down the voltage based on the required output.

- Rectification and Filtering: The transformed AC is converted back into DC through another rectifier and filtered to remove any remaining ripples.

- Feedback Mechanism: A feedback control circuit monitors the output voltage and sends this information to the PWM controller, which adjusts the switching duty cycle to maintain a stable output.

How AC Input is Converted to DC

The AC input is passed through an input filter that removes noise and harmonics. It then enters the rectifier, where a bridge of diodes converts the alternating current into pulsating DC. This DC is smoothed by capacitors to reduce ripples and prepare it for the high-frequency switching stage.

Role of High-Frequency Switching

High-frequency switching is a core feature of SMPS. By turning the switching element (typically a MOSFET) on and off rapidly, the SMPS minimizes power loss and controls the amount of energy passed to the transformer. This allows for efficient power conversion with minimal heat generation.

Use of Transformers for Voltage Conversion

The transformer in an SMPS operates at a much higher frequency than those in traditional power supplies, which allows it to be smaller and more efficient. It steps the voltage up or down depending on the design, while also providing isolation between the input and output for safety.

Feedback Mechanism for Voltage Regulation

The feedback mechanism continuously monitors the output voltage. If it detects any deviation from the desired output, it adjusts the duty cycle of the switching element. This is done via the PWM controller, which increases or decreases the time the switch is on to maintain the output voltage within a specified range.

Types of SMPS Configurations

Buck Converter (Step-Down)

A buck converter reduces the input voltage to a lower output voltage. It’s widely used in DC-DC conversion for applications like power supplies for low-voltage circuits in computers and mobile devices.

Boost Converter (Step-Up)

A boost converter increases the input voltage to a higher output voltage. It’s commonly used in battery-powered devices, where the input voltage needs to be boosted to supply power to higher voltage components.

Buck-Boost Converter

A buck-boost converter can either step up or step down the voltage depending on the input. This makes it a versatile option for devices that require a range of voltage inputs or need to adapt to varying supply conditions.

Flyback Converter

The flyback converter is used in isolated power supply designs, where electrical isolation between input and output is required. It’s commonly found in low-power applications like adapters and small power supplies.

Applications of SMPS

SMPS in Computers, Telecom Equipment, Industrial Machinery, etc.

SMPS is widely used in computers to convert AC power to multiple DC voltages needed by different components. In telecom equipment, SMPS ensures that sensitive circuits get clean and stable power. Industrial machinery benefits from SMPS due to its ability to handle high power loads efficiently.

Power Supply in Household Electronics

Household devices such as televisions, microwave ovens, and gaming consoles rely on SMPS for their compact size, energy efficiency, and ability to deliver consistent power.

Use in Renewable Energy Systems

SMPS plays a key role in renewable energy systems such as solar inverters, where they convert energy from solar panels into usable power while minimizing energy losses.

Advantages and Disadvantages

Key Benefits

- High Efficiency: SMPS achieves efficiency levels greater than 90%, significantly reducing energy waste.

- Smaller Size and Weight: By operating at high frequencies, SMPS allows for the use of smaller transformers and components, reducing the overall size and weight of the unit.

- Less Heat Dissipation: Due to its efficient power conversion, SMPS generates much less heat compared to linear power supplies, eliminating the need for bulky heatsinks.

Drawbacks

- Complex Design: The design of SMPS is more complex due to the need for precise control and feedback mechanisms, which may increase development time and cost.

- Electromagnetic Interference (EMI): High-frequency switching can introduce EMI, which can interfere with nearby sensitive equipment. This necessitates additional filtering components to reduce noise.

Conclusion

In conclusion, Switch Mode Power Supplies (SMPS) have revolutionized power conversion with their high efficiency, compact design, and flexibility. They are essential in a wide range of applications, from consumer electronics to industrial systems. Despite the complexity and potential EMI issues, their benefits far outweigh the drawbacks, making SMPS the preferred choice for modern power supply designs. As technology advances, we can expect further improvements in efficiency and reduced EMI, making SMPS even more integral to future power systems.