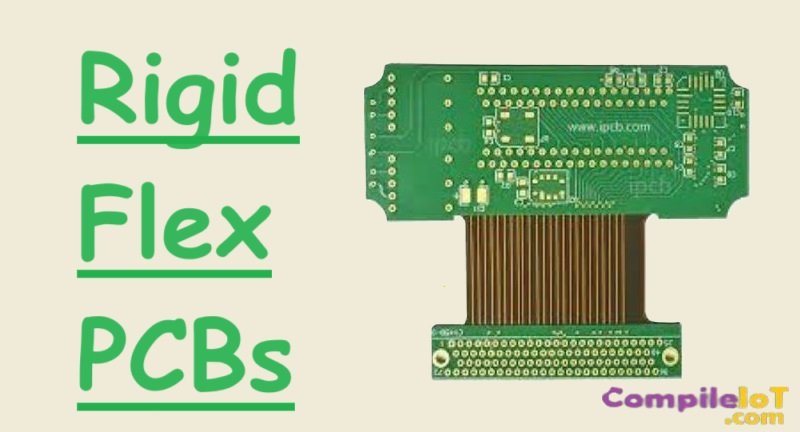

Rigid Flex PCBs

Rigid-flex PCBs are a hybrid solution that combines the best features of both rigid and flexible PCBs. They consist of multiple layers of rigid PCB material interconnected by flexible circuits, allowing for both rigid and flexible areas within the same PCB. This flexibility opens up new possibilities in terms of design, form factor, and reliability. Traditional rigid PCBs have long been the standard choice, but in recent years, rigid-flex PCBs have gained popularity for their unique advantages. In this article, we will explore the benefits of using rigid-flex PCBs in your electronic designs.

What are Rigid-Flex PCBs?

Rigid-flex printed circuit boards (PCBs) are a specialized type of PCB that blend both flexible and rigid board technologies within a single application. Typically, these boards comprise layers of flexible circuit substrates that are interconnected with one or more rigid boards, either externally or internally, depending on the specific design requirements. The flexible substrates are engineered to maintain a constant level of flexibility and are often shaped into a curved form during the manufacturing process or during installation.

Advantages of Rigid-Flex PCBs

Rigid-flex PCBs offer several advantages over traditional rigid or flexible PCBs:

- Space-saving: Rigid-flex PCBs can be designed to fit into tight spaces, allowing for more compact and lightweight electronic devices.

- Reliability: The combination of rigid and flexible sections provides enhanced durability and resistance to mechanical stress, reducing the risk of failure due to bending or vibration.

- Cost-effective: While the initial cost of rigid-flex PCBs may be higher than traditional PCBs, they can often reduce overall manufacturing and assembly costs by eliminating the need for connectors, cables, and additional interconnects.

- Improved signal integrity: Rigid-flex PCBs can minimize signal loss and impedance issues, resulting in better signal quality and reduced electromagnetic interference.

- Design flexibility: Rigid-flex PCBs offer more design freedom, allowing for complex three-dimensional shapes and the integration of multiple functions into a single board.

Design Considerations

When designing a rigid-flex PCB, there are several important considerations to keep in mind:

- Bend radius: The bend radius determines how tightly the PCB can be flexed without causing damage to the circuitry. It is crucial to specify the appropriate bend radius for each flexible section to ensure reliable operation.

- Layer stackup: The layer stackup defines the arrangement of the rigid and flexible layers within the PCB. It is essential to carefully plan the stackup to achieve the desired flexibility and functionality while maintaining signal integrity.

- Component placement: Proper component placement is crucial to ensure that the components can withstand the mechanical stress and movement of the flexible sections. It is important to consider the size, weight, and thermal characteristics of the components when placing them on the PCB.

- Routing and trace spacing: The routing and trace spacing should be optimized to prevent any mechanical stress or interference between the flexible and rigid sections. It is necessary to follow design guidelines and consider factors such as trace width, spacing, and impedance control.

- Testing and assembly: Rigid-flex PCBs require specialized testing and assembly techniques. It is important to work closely with your manufacturer to ensure proper fabrication, assembly, and testing of the boards.

Applications of Rigid-Flex PCBs

Rigid-flex PCBs are widely used in various industries and applications, including:

- Consumer electronics

- Medical devices

- Aerospace and defense

- Automotive

- Industrial automation

These applications benefit from the unique combination of flexibility, durability, and space-saving capabilities offered by rigid-flex PCBs.

Conclusion

Rigid-flex PCBs provide a versatile and reliable solution for applications that require both flexibility and durability. By combining the benefits of rigid and flexible PCBs, these boards offer space-saving designs, improved reliability, and enhanced signal integrity. When designing a rigid-flex PCB, it is essential to consider factors such as bend radius, layer stackup, component placement, routing, and testing. With proper design and manufacturing techniques, rigid-flex PCBs can greatly enhance the performance and functionality of your electronic devices.