PCBONLINE: Quality, Speed and Innovation in PCB Production

A reliable electronics manufacturing partner can significantly impact the success of your project. PCBONLINE offers quality, efficiency and transparency, which ensures your products meet both performance and time-to-market goals.

With over two decades of experience, PCBONLINE has established itself as a trusted name in the electronics manufacturing industry. Their advanced capabilities in PCB fabrication, PCB assembly and EMS (Electronics Manufacturing Services) have made them a go-to solution for businesses worldwide. Here’s why PCBONLINE should be your go-to solution for all your electronics production needs.

About PCBONLINE

Founded in 1999, PCBONLINE is more than just a PCB manufacturer—it is a comprehensive electronics manufacturing partner. Operating as a direct factory outlet, PCBONLINE eliminates middlemen, offering clients greater control, better pricing and higher transparency. This unique model allows the company to prioritize quality and efficiency without compromise.

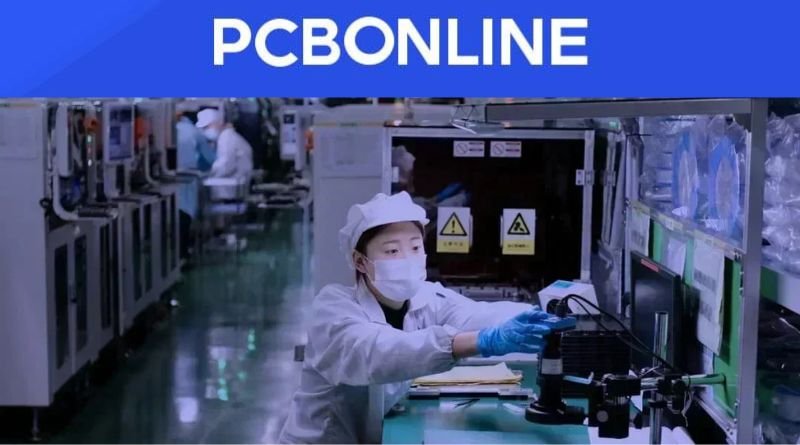

PCBONLINE boasts state-of-the-art facilities, including two large PCB manufacturing plants and a high-tech EMS (PCBA) factory. These facilities are equipped with the latest technologies for PCB production and assembly, ensuring that every project meets the highest standards of precision and durability.

The company’s team includes over 100 experienced engineers and 1,500 skilled technicians who are passionate about innovation and problem-solving. Their expertise spans a wide range of applications, including aerospace, automotive, medical devices, telecommunications and consumer electronics.

PCBONLINE Products and Services

All-in-one Manufacturing Services

PCBONLINE simplifies electronics production with:

- PCB Fabrication: From prototypes to large-scale production.

- PCB Assembly: SMT, THT, and mixed assembly services.

- End-to-End EMS: Design support, assembly, and product testing.

Wide Range of PCB Types

PCBONLINE offers PCBs designed for various needs:

- Rigid PCBs: Reliable for industrial and consumer electronics.

- Flexible PCBs: Perfect for compact and adaptable designs.

- HDI PCBs: Ideal for complex and dense circuits.

- Ceramic PCBs: Best for high-frequency and high-temperature applications.

- Aluminum PCBs: Excellent for thermal management in LED and power systems.

High-Quality Finishes and Materials

Choose from a variety of surface finishes and laminates:

- Finishes: ENIG, HASL, immersion silver, and gold plating.

- Materials: Specialty options like Rogers, Teflon, and halogen-free laminates.

Industries where PCBONLINE Serve

PCBONLINE supports a range of industries:

- Aerospace and Defense: High-reliability solutions.

- Automotive: Advanced PCBs for EVs and in-vehicle systems.

- Medical Electronics: Boards for diagnostic and medical devices.

- Industrial Electronics: For automation, robotics, and control systems.

- Telecommunications: High-frequency PCBs for 5G and networking.

Key Features of PCBONLINE

1. Turnaround Times

In today’s fast-paced industry, time is critical. PCBONLINE offers ultra-fast delivery options, with turnaround times as short as 8 hours for urgent projects. Their efficient two-shift production system ensures that deadlines are met consistently, allowing you to bring your products to market faster.

2. Pricing

PCBONLINE’s pricing model is both transparent and competitive. By eliminating brokers, they provide cost-efficient solutions without hidden fees. Customers can also benefit from special discounts like free samples for batch orders and coupons worth up to $100. This customer-centric approach ensures exceptional value for every project.

3. Direct Factory Access

Unlike brokers or intermediaries, PCBONLINE provides direct factory access, giving clients full control over their projects. This model ensures that customers receive superior quality, optimized designs and streamlined communication—all at a fraction of the cost.

4. Quality Assurance

PCBONLINE prioritizes quality through stringent standards and certifications. Their facilities are ISO9001, RoHS, REACH, and UL certified, and all processes adhere to IPC-A-600 and IPC-A-610 standards. With a focus on traceability, every product undergoes rigorous testing to guarantee reliability and performance.

5. Customer Support

PCBONLINE offers 24/7 customer support, with dedicated engineering teams providing personalized solutions tailored to your needs. Whether it’s design assistance, order updates or technical guidance, their experts are always available to ensure a smooth experience.

6. Experience

With over two decades of expertise, PCBONLINE has successfully served industries such as aerospace, automotive, telecommunications, and medical devices. Their extensive knowledge and ability to handle complex projects make them a trusted partner for high-end industries.

Advanced Manufacturing Capabilities

1. PCB Fabrication Processes

PCBONLINE employs cutting-edge manufacturing techniques to produce reliable and high-performance PCBs. These include:

- Copper Etching: Precise circuit formation by removing excess copper from the substrate.

- Immersion Copper: Chemical deposition to ensure robust copper connections.

- Vertical Continuous Plating (VCP): Advanced plating methods for consistent quality and durability.

- Automatic Electroplating: Provides enhanced surface finishes like hard gold, suitable for wear-resistant applications.

2. PCB Assembly

PCBONLINE’s assembly capabilities are designed to meet the highest precision standards. They specialize in:

- SMT (Surface-Mount Technology): Automated placement of components with exceptional accuracy.

- THT (Through-Hole Technology): Reliable assembly for components requiring mechanical strength.

- Inspection and Testing: Rigorous adherence to IPC-A-610 ensures defect-free assembly.

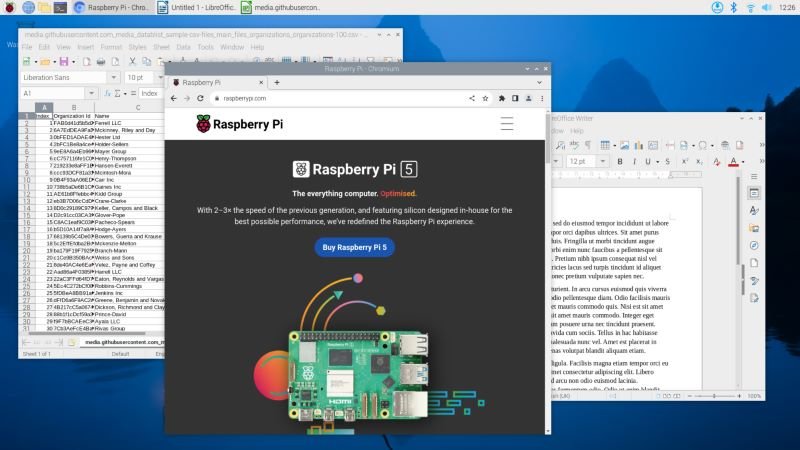

3. Technology-Driven Solutions

PCBONLINE leverages advanced technologies to streamline the manufacturing process:

- Instant Online Quoting System: Reduces quoting time from days to just minutes, ensuring faster order placement.

- DFX Services (DFM, DFA, DFT): Expert design optimization for manufacturability, assembly, and testing.

Commitment to Sustainability

PCBONLINE is dedicated to protecting the environment and ensuring that its manufacturing processes are as sustainable as possible. By adopting eco-friendly practices, the company actively works to minimize its environmental footprint.

- Efforts to Reduce Impact: PCBONLINE employs resource-efficient techniques, such as waste reduction, energy conservation and sustainable material sourcing, throughout its production processes.

- Employee Training: To promote a culture of environmental responsibility, employees receive regular training on eco-friendly practices, ensuring that sustainability remains a core focus at every level of the organization.

- Compliance: The company adheres to global environmental standards, including RoHS and REACH, ensuring safe and responsible production.

Why Choose PCBONLINE?

PCBONLINE sets itself apart with a unique combination of features that cater to customers’ diverse needs:

- One-Stop Manufacturing: From PCB fabrication to assembly and testing, PCBONLINE provides end-to-end services under one roof, eliminating the need for multiple vendors.

- No MOQ Limits: Whether it’s a single prototype or mass production, PCBONLINE caters to projects of all sizes.

- Cost-Effective Solutions: With transparent pricing, bulk discounts, and cost-saving design optimization, customers get the best value for their money.

- Advanced EMS Capabilities: Cutting-edge technology and skilled engineering teams ensure precision, reliability, and efficiency in every project.

- Value-Added Services: Customers enjoy free perks, such as Gerber/BOM file checks, DFM analysis, and sample offers, to enhance project quality and reduce risks.

How to Get Started?

Getting started with PCBONLINE is simple and streamlined:

- Contact PCBONLINE: Visit the website to access a user-friendly platform for inquiries and assistance.

- Request a Quote: Use their instant online quotation tool to receive accurate pricing for your project in minutes.

- Submit Your Design Files: Upload your Gerber and BOM files for review and optimization, with free checks included.

- Track Your Project: Benefit from real-time project tracking to stay updated on progress from start to finish.

PCBONLINE’s customer-first approach ensures that support is available 24/7, with a team of dedicated engineers ready to provide guidance and solutions.

Conclusion

In conclusion, PCBONLINE is more than just a manufacturer—it’s a trusted partner for all your electronics production needs. With a strong commitment to quality, sustainability, and customer satisfaction, PCBONLINE delivers superior results for projects of any complexity.

From rapid prototyping to mass production, PCBONLINE’s comprehensive services, advanced capabilities, and customer-focused approach make it the ideal choice for industries worldwide. Start your journey with PCBONLINE today and experience the difference in quality, efficiency, and innovation.