Exploring Potentiometers: How They Work and Where They are Used?

Introduction

A potentiometer, often abbreviated as “pot,” is a three-terminal variable resistor that adjusts voltage levels within a circuit. It functions by allowing a user to manually alter the resistance, typically by rotating or sliding a control, which changes the output voltage. Potentiometers are widely used in applications like volume control in audio systems, tuning, and calibration of circuits.

Basic Concept of Variable Resistors

Variable resistors are electronic components whose resistance can be adjusted over a certain range. Unlike fixed resistors, whose resistance value is constant, variable resistors allow for fine-tuning of current and voltage in circuits. Potentiometers, a type of variable resistor, achieve this by altering the length of the resistive path that current travels through.

Overview of Their Importance and Applications in Electronic Circuits

Potentiometers are essential in many electronic applications, offering precise control over circuit parameters such as voltage and current. They are commonly found in audio equipment for volume control, lighting dimmers, and as position sensors in joysticks and other control devices. Their versatility, ease of use, and ability to fine-tune circuit behavior make them indispensable in both consumer electronics and industrial control systems.

Working Principle of Potentiometers

Explanation of How a Potentiometer Works

A potentiometer works by varying the resistance along its resistive track. It has three terminals: two connected to the ends of the resistive element, and a third connected to a wiper that moves along the track. By adjusting the wiper’s position, the user effectively changes the length of the resistive path between the terminals. This alters the voltage output across the circuit.

The Relationship Between Resistance, Wiper Position, and Voltage

As the wiper moves closer to one end of the resistive element, the resistance between the wiper and that end decreases, causing a corresponding increase or decrease in voltage, depending on the configuration. When the wiper is at the midpoint, the resistance is divided equally, and the output voltage is half of the input voltage. Thus, a potentiometer can function as a voltage divider, providing a variable output based on the wiper’s position.

Ohm’s Law in Relation to Potentiometers

According to Ohm’s Law, V = IR, the voltage (V) across a resistor is proportional to the current (I) flowing through it and its resistance (R). In a potentiometer, as the resistance changes due to the wiper’s movement, the voltage drop across the resistor also changes. This makes potentiometers an effective way to control voltage levels in a circuit dynamically.

Types of Potentiometers

Rotary Potentiometers: Description and Common Uses

Rotary potentiometers are the most common type and consist of a circular resistive track with a rotating wiper. As the user turns the knob, the wiper moves along the track, changing the resistance. These potentiometers are commonly used in volume controls for audio equipment, where they adjust the signal strength. Rotary potentiometers are favored for their simplicity, durability, and ease of use.

Linear Potentiometers: Description and Applications

Linear potentiometers have a straight resistive track, and the wiper moves along this track in a linear fashion. These types are often found in applications requiring precise measurement or control, such as in faders on audio mixers or in position sensing systems. The linear motion of the wiper provides a direct, proportional change in resistance, making them suitable for applications where consistent, linear control is needed.

Digital Potentiometers: How They Differ from Mechanical Types

Digital potentiometers, or “digipots,” function similarly to traditional potentiometers but are controlled electronically rather than mechanically. Instead of a physical wiper moving along a resistive track, digital potentiometers use semiconductor switches to select resistance values from a preset range. These are often used in systems where automated control is needed, such as in digital audio equipment or in feedback systems.

Comparison of Different Types with Advantages and Disadvantages

- Rotary Potentiometers: Simple to use, reliable, and affordable. However, they can wear out over time due to mechanical movement.

- Linear Potentiometers: Offer precise, proportional control, making them ideal for applications requiring accuracy. Their linear design, though, can make them bulkier compared to rotary pots.

- Digital Potentiometers: Provide precise, repeatable adjustments and can be controlled remotely or by software. Their main disadvantages include higher cost and complexity compared to mechanical types.

Construction and Parts

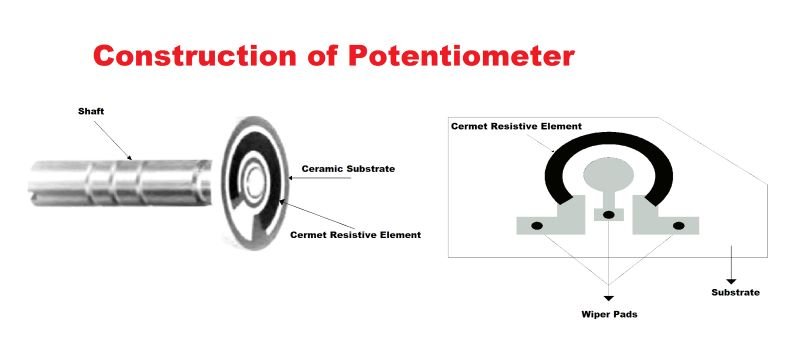

Resistive Element: Materials Used (e.g., Carbon, Cermet)

The resistive element is the core of a potentiometer, providing the variable resistance needed for its operation. This element is typically made from materials like carbon, cermet (a composite of ceramic and metal), or wire wound in high-power applications. Carbon is common in low-cost potentiometers, offering a balance of performance and affordability. Cermet is used in more precise applications due to its stability and durability over a wide temperature range.

Wiper: How it Functions and Moves

The wiper is a movable contact that slides along the resistive element, adjusting the resistance. As the user turns the knob (in a rotary potentiometer) or moves the slider (in a linear potentiometer), the wiper moves accordingly, changing the point of contact on the resistive element. This movement alters the resistance between the wiper and the terminals, allowing for continuous adjustment of the output voltage.

Terminals: How They Are Connected in a Circuit

Potentiometers have three terminals. The outer two terminals are connected to either end of the resistive element, and the middle terminal (connected to the wiper) provides the adjustable output. In typical usage, one of the outer terminals is connected to the power source, and the wiper’s terminal delivers the variable voltage. The third terminal may be grounded or left unconnected, depending on the circuit’s design.

Applications of Potentiometers

Volume Control in Audio Devices

One of the most well-known applications of potentiometers is in volume control for audio devices. Rotary potentiometers are used in stereo systems and other audio equipment to adjust the output signal to speakers. By varying the resistance, the potentiometer controls the level of the audio signal, allowing users to increase or decrease the volume smoothly.

Tuning and Calibration in Circuits

Potentiometers are frequently used in circuits that require fine-tuning or calibration. For instance, they are employed in radio tuning systems to adjust frequency or in electronic measurement equipment where precise calibration is needed. The ability to make small, precise adjustments in resistance makes potentiometers ideal for such applications.

Voltage Divider Circuits

A common use of potentiometers is as a voltage divider. In this configuration, the potentiometer splits the input voltage into two parts, depending on the position of the wiper. This allows for adjustable output voltage, which can be used in signal conditioning, feedback circuits, or controlling devices such as LEDs and motors.

Sensors (e.g., Position Sensors in Joysticks and Controls)

Potentiometers can also be used as position sensors, particularly in joysticks or other control systems. As the user moves the joystick or control lever, the wiper moves along the resistive element, providing a variable voltage that indicates the position. This voltage can then be used by the system to determine direction, speed, or other factors in a control loop.

Advantages and Limitations

Benefits of Using Potentiometers in Circuits

- Adjustability: Potentiometers provide a simple way to adjust resistance and voltage without altering the circuit design. This makes them highly versatile components.

- Cost-Effective: Mechanical potentiometers are relatively inexpensive and widely available.

- Ease of Use: Potentiometers are user-friendly and require no specialized knowledge to operate, making them ideal for consumer products and hobbyist projects.

- Versatility: They are used in a wide range of applications, from audio equipment to industrial controls and sensors.

Limitations such as Wear and Mechanical Issues

- Wear and Tear: Mechanical potentiometers can degrade over time due to constant movement of the wiper along the resistive element, which can lead to noise, inaccuracies, or complete failure.

- Size: Some potentiometers, especially high-power or precision types, can be bulky, limiting their use in compact electronic designs.

- Mechanical Issues: External factors such as dust, dirt, or physical damage can affect performance, particularly in rotary and linear types that rely on mechanical movement.

Impact of Resistance Tolerance and Linearity

- Resistance Tolerance: Potentiometers have a certain tolerance, meaning the actual resistance can vary slightly from the rated value. This can introduce slight inaccuracies in sensitive circuits.

- Linearity: In some potentiometers, the relationship between the wiper position and the resistance may not be perfectly linear, which can affect applications that require precise, proportional control. Linear potentiometers are designed to address this, but even they can exhibit non-ideal behavior under certain conditions.

How to Choose a Potentiometer

Factors to Consider (Resistance Range, Power Rating, Taper, etc.)

When selecting a potentiometer for your project, consider the following factors:

- Resistance Range: The resistance value is one of the most important specifications. Typical values range from 1kΩ to 1MΩ, depending on the application. For precise voltage control, choose a potentiometer with an appropriate resistance value that suits the circuit’s needs.

- Power Rating: Potentiometers have a maximum power rating, usually measured in watts. Ensure that the potentiometer can handle the power dissipated by the circuit without overheating or failing. Standard ratings range from 0.1W to 5W for most applications.

- Taper (Logarithmic vs. Linear): Taper refers to how the resistance changes as you move the wiper.

- Linear Taper: Resistance changes evenly as the wiper moves. Used in applications where proportional control is needed, such as in voltage dividers.

- Logarithmic Taper: Resistance changes more gradually at first and more sharply later. Often used in audio controls like volume knobs, where human perception of sound requires non-linear control.

- Size and Form Factor: Consider the physical dimensions of the potentiometer, particularly if space is limited. Rotary, linear, or digital forms are available depending on how you want to control resistance.

- Durability and Environment: Choose materials (e.g., carbon, cermet) that can withstand the environment, especially if the potentiometer will be exposed to harsh conditions like dust, moisture, or extreme temperatures.

Example of Choosing the Right Potentiometer for Specific Applications

For instance, if you’re designing a guitar amplifier:

- Resistance Value: Choose a potentiometer with a resistance range of 10kΩ to 100kΩ, depending on how fine the volume control needs to be.

- Taper: A logarithmic taper is preferred for volume control, as it matches the way humans perceive sound levels.

- Power Rating: Ensure a power rating of at least 0.5W to handle the current without damaging the component.

- Size: Select a rotary potentiometer that can fit into the amplifier’s control panel.

Potentiometer vs Rheostat

Key Differences Between Potentiometers and Rheostats

- Number of Terminals: A potentiometer has three terminals, while a rheostat typically has two terminals. In a potentiometer, the third terminal (connected to the wiper) allows for adjustable voltage output. In contrast, a rheostat only adjusts current by varying the resistance between two terminals.

- Function: A potentiometer is primarily used for controlling voltage (e.g., as a voltage divider), whereas a rheostat is used to control current. Rheostats can handle higher currents, making them ideal for high-power applications.

- Applications:

- Potentiometers: Used in devices where precise voltage control is needed, such as audio systems, sensors, and tuning circuits.

- Rheostats: Found in applications where controlling current is essential, such as in light dimmers, heating elements, and motor speed control.

Where Each is Used in Practical Applications

- Potentiometer: In audio systems, potentiometers adjust the volume by controlling the voltage to the speaker. They are also used in joysticks to sense movement by adjusting voltage based on position.

- Rheostat: Rheostats are used in industrial settings to control motor speed by varying the current or in large lighting systems where current regulation is critical.

FAQ Section

What is the typical lifespan of a potentiometer?

Potentiometers have a mechanical lifespan based on the number of rotations or adjustments they can handle before wear causes failure. High-quality potentiometers can last for tens of thousands of cycles, while cheaper versions may wear out sooner.

How do I connect a potentiometer in a circuit?

A potentiometer has three terminals. For use as a variable resistor, connect two of the terminals (one outer and the wiper). For use as a voltage divider, connect all three terminals: the outer ones to the input voltage and ground, and the wiper to the output.

Can a potentiometer be used for both AC and DC applications?

Yes, potentiometers can be used with both AC and DC, but you need to ensure the component’s power rating and resistance values are appropriate for the type of current.

What are the most common types of potentiometer failure?

Potentiometers can fail due to mechanical wear, dirt or debris interfering with the wiper, or overheating if power ratings are exceeded.

How do I know which taper to choose for my application?

Use a linear taper for applications where you need consistent, proportional control (like in a voltage divider). Use a logarithmic taper for audio applications or any scenario where control needs to follow a logarithmic curve, like volume adjustment.

Conclusion

In conclusion, Potentiometers are versatile, essential components in both everyday electronics and specialized applications. They allow for smooth control of voltage and current, providing a user-friendly interface for adjusting various parameters like volume, tuning, and brightness. Understanding how potentiometers work, the different types available, and how to select the right one for your project is crucial to optimizing circuit performance. Whether used as a voltage divider, position sensor, or variable resistor, potentiometers offer practical solutions in countless electronic designs, making them a fundamental part of modern electronics.