Types of Soil Moisture Sensors

Soil moisture sensors are essential tools for monitoring and managing irrigation in various agricultural and gardening applications. These sensors provide valuable data on the moisture content of the soil, helping farmers and gardeners make informed decisions about watering schedules and irrigation practices. In this blog post, we will explore different types of soil moisture sensors and their features.

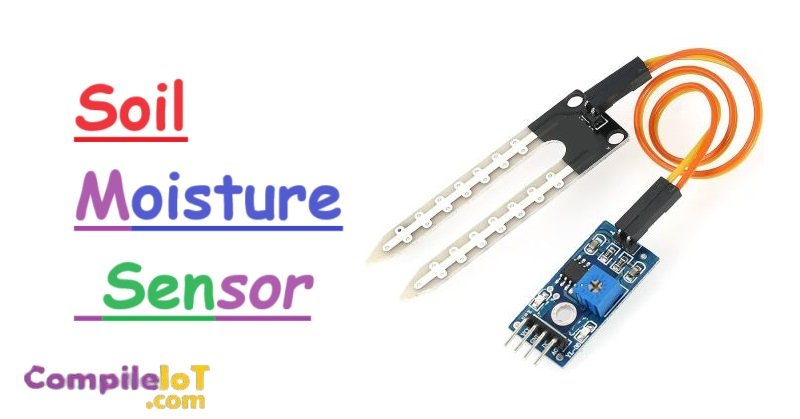

What is a Soil Moisture Sensor?

A soil moisture sensor is a device used to measure the amount of moisture present in the soil. It provides valuable information about the water content in the soil, which is crucial for effective irrigation and plant health. With the help of a soil moisture sensor, farmers, gardeners and researchers can determine the optimal time to water their plants, prevent overwatering or underwatering, and conserve water resources.

What Do Soil Sensors Measure?

Soil sensors measure the soil moisture content, which is an essential parameter for understanding the water status of the soil. They provide information about the amount of water available to the plants and help in determining when and how much water should be applied for optimal plant growth.

In addition to measuring soil moisture, some advanced soil sensors can also measure other important soil parameters such as soil temperature, soil conductivity and soil salinity. These additional measurements can give a more comprehensive understanding of the soil conditions and help in making informed decisions regarding irrigation and fertilization.

Working Principle of Soil Moisture Sensor

The working principle of a soil moisture sensor is based on the electrical conductivity of the soil. It measures the resistance between two electrodes embedded in the soil, which is directly related to the moisture content. The sensor typically consists of two or more electrodes, a circuit board and a protective casing.

When the soil is dry, it has a high resistance to the flow of electric current. As the soil moisture increases, the resistance decreases. This change in resistance is measured by the sensor and converted into a corresponding moisture level reading. The sensor is calibrated to provide accurate readings based on the specific soil type and the needs of the plants being grown.

Types of Soil Moisture Sensors

Here are some common types of soil moisture sensors:

Capacitance Sensors

Capacitance sensors work by measuring the dielectric constant of the soil, which is directly related to the soil moisture content. These sensors consist of two electrodes that are inserted into the soil. The moisture in the soil affects the electrical capacitance between the electrodes, which is then measured and converted into a moisture reading. Capacitance sensors are known for their accuracy and reliability.

They can provide real-time data on soil moisture levels and are suitable for a wide range of soil types. These sensors are also easy to install and require minimal maintenance. These sensors are commonly used in a wide range of applications, from touchscreens and proximity sensors to level and pressure measurement devices.

How Capacitance Sensors Work

Capacitance sensors work based on the principle of capacitance, which is the ability of two conductive surfaces to store an electric charge when a voltage is applied across them. When a capacitance sensor is in proximity to an object or substance, the capacitance between the sensor and the object changes. This change in capacitance is then measured by the sensor and converted into a corresponding electrical signal.

Capacitance sensors consist of two conductive surfaces, typically in the form of electrodes, separated by a dielectric material. The dielectric material can be air, a liquid or a solid, depending on the application. When an object or substance comes close to the sensor, it affects the electric field between the electrodes, resulting in a change in capacitance.

Considerations for Using Capacitance Sensors

- Environmental factors: Capacitance sensors can be affected by environmental factors such as temperature, humidity and electromagnetic interference. It is important to consider these factors and take appropriate measures to ensure accurate measurements.

- Material properties: The dielectric properties of the material being measured can affect the capacitance measurement. It is important to select a sensor that is suitable for the specific material and application.

- Calibration: Capacitance sensors may require periodic calibration to maintain accuracy. This calibration process involves comparing the sensor’s output to a known reference and making any necessary adjustments.

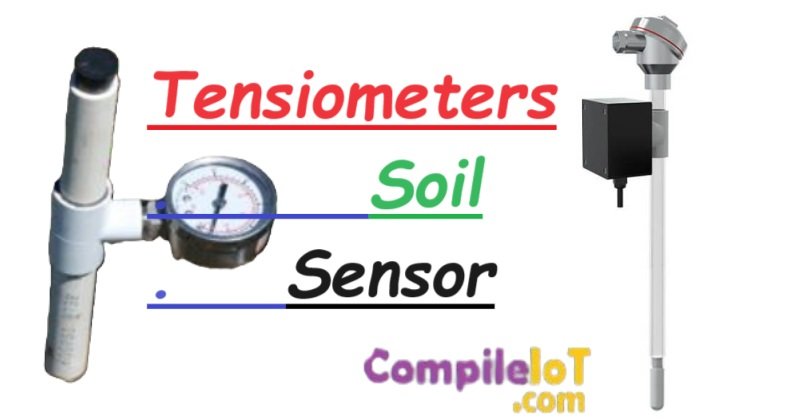

Tensiometers

Tensiometers are another type of soil moisture sensor that measures the tension or suction of the soil. These sensors consist of a porous ceramic cup filled with water and a vacuum gauge. The ceramic cup is buried in the soil, and as the soil dries out, water is drawn from the cup, creating a negative pressure or tension. The vacuum gauge measures this tension, which is then correlated to the soil moisture content.

Tensiometers are particularly useful for measuring soil moisture in sandy soils or soils with low water-holding capacity. They provide accurate and reliable data on the soil moisture status and can help prevent overwatering or underwatering of plants.

How Do Tensiometers Work?

Tensiometers work based on the principle of measuring the force required to overcome the surface tension of a liquid or the pressure exerted by a gas. They typically consist of a probe or sensor that comes into contact with the fluid or gas, and a measuring device or display that shows the tension or pressure reading.

There are different types of tensiometers available, depending on the specific application and requirements:

1. Liquid Tensiometers

Liquid tensiometers are used to measure the surface tension of liquids. They often consist of a thin glass tube or capillary that is partially submerged in the liquid. The liquid will rise or fall in the capillary based on its surface tension, and the measurement can be read from a scale on the tube.

2. Gas Tensiometers

Gas tensiometers, also known as pressure tensiometers, are used to measure the pressure of gases. They typically consist of a pressure sensor or transducer that is connected to the gas source. The pressure reading can be displayed digitally or on a gauge.

3. Contact Angle Tensiometers

Contact angle tensiometers are used to measure the contact angle between a liquid and a solid surface. This measurement provides insights into the wetting and adhesion properties of the liquid on the surface. Contact angle tensiometers often use advanced imaging techniques to capture and analyze the contact angle.

Applications of Tensiometers

Tensiometers have a wide range of applications across various industries. Some common applications include:

1. Surface Coating and Printing

Tensiometers are used in the surface coating and printing industry to ensure the proper wetting and adhesion of coatings and inks. By measuring the surface tension of the liquid, manufacturers can adjust the formulation and application process to achieve the desired results.

2. Pharmaceutical Industry

In the pharmaceutical industry, tensiometers are used to measure the surface tension of liquids, such as drug formulations. This information is crucial for determining the stability and effectiveness of the product.

3. Oil and Gas Industry

Tensiometers are used in the oil and gas industry to measure the interfacial tension between oil, water, and gas phases. This data helps in the optimization of oil recovery processes and the design of efficient separation systems.

4. Research and Development

Tensiometers play a vital role in research and development, where understanding the behavior of fluids is essential. They are used in various fields, including materials science, chemistry, and biology, to study the surface properties of liquids and their interactions with other materials.

Time Domain Reflectometry (TDR) Sensors

Time Domain Reflectometry (TDR) sensors use electromagnetic waves to measure the soil moisture content. These sensors work by sending a pulse of electromagnetic energy into the soil and measuring the time it takes for the pulse to travel back to the sensor. The moisture content of the soil affects the speed at which the pulse travels, allowing the sensor to determine the moisture level.

TDR sensors are known for their accuracy and versatility. They can be used in a wide range of soil types and provide real-time data on soil moisture levels. However, they are typically more expensive than other types of soil moisture sensors.

How TDR Sensors Work

TDR sensors work on the principle of sending an electrical pulse down a conductor and measuring the time it takes for the pulse to be reflected back. The time it takes for the pulse to travel and return is directly related to the physical property being measured. For example, in soil moisture measurement, TDR sensors are used to determine the water content in the soil. The electrical pulse is sent down a probe inserted into the soil, and the reflected pulse is analyzed to calculate the moisture content. The more moisture in the soil, the slower the pulse travels and returns.

In addition to soil moisture, TDR sensors can also be used to measure other properties such as soil salinity, temperature, and electrical conductivity. In civil engineering, TDR sensors are used to monitor the health of structures like bridges and dams by measuring changes in the electrical properties of the materials.

Applications of TDR Sensors

TDR sensors have found applications in a wide range of industries:

- Agriculture: TDR sensors are commonly used in agriculture for soil moisture measurement, allowing farmers to optimize irrigation and improve crop yield.

- Environmental monitoring: TDR sensors can be used to monitor soil conditions, groundwater levels, and contamination in environmental studies.

- Civil engineering: TDR sensors are used to monitor the health of structures like bridges and dams, detecting changes in moisture content and other physical properties.

- Geotechnical engineering: TDR sensors are used to measure soil properties for slope stability analysis, foundation design, and construction quality control.

- Industrial applications: TDR sensors can be used for moisture measurement in materials like concrete, wood, and textiles, ensuring quality control in manufacturing processes.

Conclusion

In conclusion, Soil moisture sensors are valuable tools for monitoring and managing irrigation in agricultural and gardening applications. Capacitance sensors, tensiometers, and time domain reflectometry (TDR) sensors are three common types of soil moisture sensors. Each type has its own advantages and is suitable for different soil types and applications. Whether you are a farmer, gardener, or landscape professional, investing in a soil moisture sensor can help you optimize your watering practices, conserve water, and promote healthy plant growth.