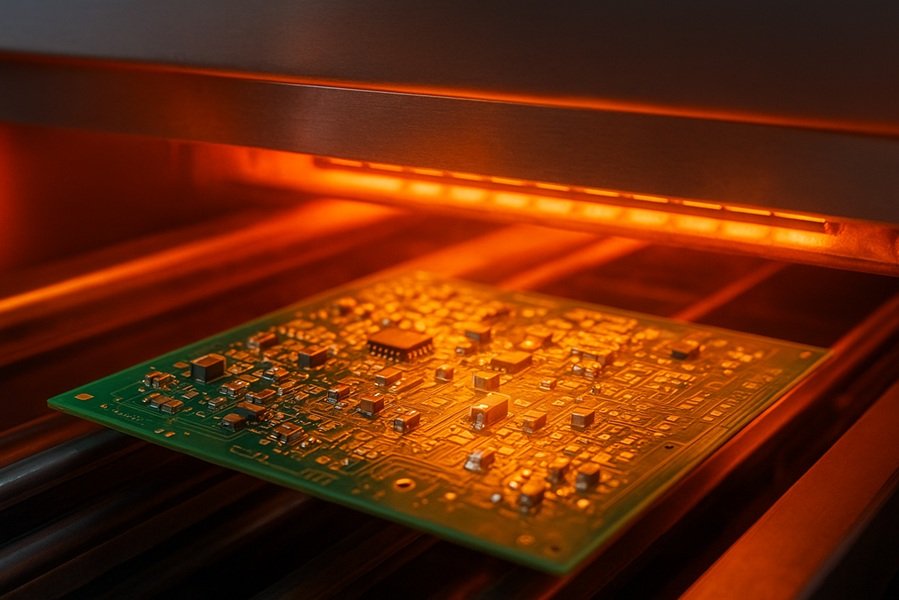

Reflow Soldering in SMT: Process, Equipment, and Best Practices

Introduction

Reflow soldering is one of the most critical processes in Surface Mount Technology (SMT), enabling the reliable attachment of electronic components to printed circuit boards (PCBs). It is widely used in modern electronics manufacturing — from smartphones and IoT devices to industrial control systems and aerospace electronics.

This technique involves melting solder paste to form strong electrical and mechanical bonds between surface-mounted components and PCB pads. As electronics become more compact and complex, understanding the reflow soldering process is essential for engineers, designers, and manufacturers aiming for high-quality, defect-free assemblies.

What is Reflow Soldering?

Reflow soldering is a heat-based process that melts solder paste — a mixture of solder powder and flux — applied to the PCB during the SMT assembly process. When heated, the solder paste reflows (melts) and then solidifies upon cooling, forming a robust joint between the component leads and PCB pads.

Unlike wave soldering, which is typically used for through-hole components, reflow soldering is specifically designed for SMD (Surface Mount Device) components, which are mounted directly onto the PCB surface without drilling.

Read This: PCB Panelization for Assembly: Methods, Design Considerations, and Depaneling Techniques

Purpose of Reflow Soldering in SMT

Reflow soldering ensures:

-

Strong mechanical connections between components and pads.

-

Low electrical resistance at the solder joints.

-

High manufacturing efficiency for mass production.

-

Consistent and reliable joints suitable for high-density circuit designs.

It is a vital stage after component placement and before electrical testing or conformal coating.

Key Steps in the Reflow Soldering Process

The reflow soldering process typically follows several well-defined stages. Each stage requires precise temperature control to ensure solder quality and prevent component damage.

1. Solder Paste Printing

-

A stencil printer applies solder paste onto the PCB pads.

-

The paste is deposited accurately using a stainless-steel stencil.

-

The paste contains flux (for cleaning and wetting) and solder powder (usually Sn-Ag-Cu alloy).

2. Component Placement

-

Pick-and-place machines position SMD components onto the solder paste deposits.

-

Components are held in place by the tackiness of the solder paste before soldering.

3. Preheating Stage

-

The preheat zone gradually raises the temperature of the board to avoid thermal shock.

-

Typical ramp-up rate: 1–3°C per second.

-

Purpose: Activate flux and remove solvents and moisture.

4. Soak Zone

-

Temperature is held between 150°C–180°C for 60–120 seconds.

-

Allows for uniform heating and flux activation.

-

Reduces temperature variations between large and small components.

5. Reflow (Peak Heating) Zone

-

The temperature rises above the solder alloy’s melting point (around 217–240°C depending on composition).

-

Solder paste melts and forms intermetallic bonds with component leads and pads.

-

The peak temperature is typically 20–40°C above the solder’s melting point but below the maximum component tolerance.

6. Cooling Zone

-

Controlled cooling solidifies the solder joints.

-

Ideal cooling rate: 3–4°C per second.

-

Prevents defects like grain coarsening or thermal stress cracks.

Types of Reflow Soldering Methods

There are several methods for reflow soldering, based on the heating technique used:

1. Infrared (IR) Reflow Soldering

-

Uses IR lamps to transfer heat to components.

-

Fast and efficient, but can lead to uneven heating (shadowing effect).

2. Convection Reflow Soldering

-

Uses hot air circulation to evenly heat the PCB.

-

The most common and reliable method used in modern SMT lines.

3. Vapor Phase Reflow (VPR)

-

Uses a boiling inert fluid to transfer heat via condensation.

-

Provides uniform temperature and prevents oxidation.

-

Ideal for high-reliability applications (military, aerospace).

4. Laser Reflow Soldering

-

Uses a focused laser beam for localized soldering.

-

Suitable for prototypes and rework on high-density boards.

Reflow Oven Equipment

A typical reflow soldering oven consists of multiple temperature-controlled zones:

| Zone | Function | Temperature Range |

|---|---|---|

| Preheat Zone | Gradual temperature increase | 100–150°C |

| Soak Zone | Flux activation & temperature equalization | 150–180°C |

| Reflow Zone | Solder melting | 217–250°C |

| Cooling Zone | Solidification | Below 150°C |

Reflow Soldering in IoT and Advanced Electronics

With the rise of IoT devices and miniaturized electronics, reflow soldering has adapted to handle:

-

Fine-pitch components (QFN, BGA, CSP).

-

High-density interconnect (HDI) boards.

-

Flexible and rigid-flex PCBs.

Modern nitrogen reflow systems and AI-controlled ovens help maintain consistency, reduce oxidation, and monitor real-time process data for smart manufacturing environments.

Safety and Environmental Considerations

-

Use lead-free solder alloys (RoHS compliant).

-

Ensure proper fume extraction to remove flux vapors.

-

Maintain oven calibration to avoid thermal runaways.

-

Dispose of solder waste per environmental standards.

Conclusion

Reflow soldering is the backbone of modern SMT assembly, ensuring precise, durable, and high-quality electronic assemblies. From consumer gadgets to industrial IoT systems, the process’s success depends on careful temperature profiling, material selection, and equipment control.

By mastering reflow soldering, manufacturers can achieve consistent reliability, reduced defects, and improved production efficiency — essential for today’s competitive electronics industry