Understanding Castellated Mounting Holes: Design, Benefits, and Applications

In this blog post we will discuss the design, benefits, disadvantages and applications of castellated mounting holes, as well as their future evolution in electronic hardware design. Let’s start with the definition of the Castellated Mounting Holes!

What are Castellated Mounting Holes?

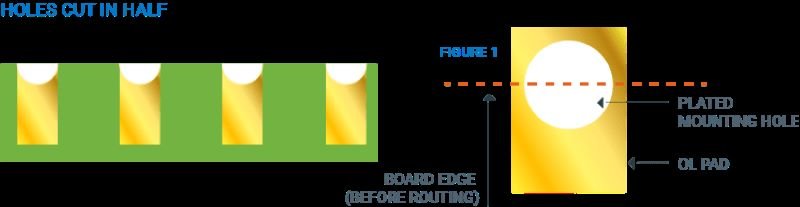

Castellated mounting holes also known as castellations. It is a unique and crucial feature in printed circuit board (PCB) design. These holes are plated through and located at the edges of a PCB, subsequently cut through using a PCB router to form half-plated holes. Typically half-circular, these holes can also take other shapes depending on specific application requirements.

Design of Castellated Holes

Hole Shape, Size, and Spacing

Castellated mounting holes generally have a round shape but can also be square or rectangular. The size of these holes is crucial as it must accommodate screws or other fasteners used for mounting. Proper spacing between holes is essential to prevent solder bridging and ensure electrical isolation between connections.

Castellation Depth and Width

The depth and width of the castellations are influenced by the thickness of the material being mounted and the size of the solder joint required. The depth must be sufficient to ensure a robust solder joint without compromising the structural integrity of the mounting hole.

Spacing and Alignment

Proper spacing and alignment of castellations are vital for facilitating soldering and assembly. Even spacing around the perimeter of the mounting hole is necessary to provide uniform support.

Thermal and Mechanical Factors

Applications subjected to high temperatures or mechanical stress may require thicker material or larger castellations to ensure stability and reliability. Thermal and mechanical considerations are pivotal in designing castellated holes to withstand diverse operating conditions.

Benefits of Castellated Mounting Holes

Let’s discuss some of the benefits of castellated mounting holes:

Space-Saving : One of the primary advantages of castellated holes is the elimination of the need for additional connectors or headers, which allows for more compact PCB designs.

Simplified Assembly : Castellated mounting holes simplify the assembly process by providing an easy way to solder components directly onto another surface, such as a larger PCB or module. This reduces assembly time and labor costs.

Increased Stability and Reliability : With notches or gaps around the perimeter, castellated mounting holes ensure strong mechanical connections between components. This enhances stability and reliability, especially in applications subjected to vibration or mechanical stress.

Improved Electrical Connection : Castellated holes offer robust electrical connections between components, minimizing signal loss and ensuring consistent electrical performance.

Modular Design : These holes facilitate a modular design approach, enhancing flexibility, scalability, and ease of upgrades or repairs.

Lower Assembly Cost : By eliminating the need for additional connectors or mounting hardware, castellated holes help reduce assembly costs.

Disadvantages of Castellated Mounting Holes

Complexity in PCB Design

Integrating castellated mounting holes into a PCB design adds complexity. Proper placement and sizing of the holes are critical to ensure alignment and compatibility with other components.

Increased Manufacturing Costs

Fabricating PCBs with castellated mounting holes requires specialized equipment and techniques to ensure precise cutting and plating, leading to higher manufacturing costs.

Risk of Solder Bridges

The design of castellated mounting holes may increase the risk of solder bridges forming between adjacent pads during the soldering process.

Limited Reusability

Once components are soldered onto a surface using castellated mounting holes, they can be challenging to remove or reuse without causing damage to the PCB or the components themselves.

Assembly Complexity

While castellated mounting holes simplify some aspects of assembly, they can introduce additional complexity, particularly in hand soldering operations or when working with automated assembly equipment.

Interference with Signal Traces

The presence of castellated mounting holes on a PCB can interfere with nearby signal traces. Designers must carefully consider the placement of these holes to avoid signal integrity issues.

Despite these disadvantages, castellated mounting holes remain a valuable option in many electronic hardware designs.

Applications of Castellated Mounting Holes

Castellated mounting holes offer versatility, reliability and space-saving benefits, making them suitable for a wide range of applications:

- Wireless Communication Modules: Castellated mounting holes are often used in radio frequency (RF) modules, such as Wi-Fi modules, Bluetooth modules, and RF transceivers. These modules benefit from the secure and compact mounting options provided by castellations.

- Internet of Things (IoT) Devices: In IoT devices, castellated mounting holes facilitate the integration of multiple components, sensors, and communication modules onto a single PCB, enabling compact and robust designs.

- Embedded Systems: In embedded systems where space is limited, castellated mounting holes are used to attach small modules to the main PCB, ensuring a secure and reliable connection.

- Wearable Technology: Wearable devices benefit significantly from the space-saving nature of castellated mounting holes, allowing for compact and efficient designs.

- Industrial Control Systems: Castellated mounting holes are used in industrial controllers, data acquisition systems, and automation equipment. They provide secure connections that can withstand harsh environmental conditions.

- Consumer Electronics: Consumer electronic devices, such as gaming consoles, media players, and smart home devices, use castellated mounting holes to integrate additional features or expand functionality.

Future Evolution of Castellated Mounting Holes

The future of castellated mounting holes in electronic hardware design is likely to be influenced by several factors:

Miniaturization Trends

As electronic devices continue to shrink in size, the demand for compact and efficient mounting solutions like castellated holes will increase.

Advanced Manufacturing Techniques

Improvements in manufacturing techniques will make the production of castellated holes more cost-effective and precise, reducing the complexity and cost associated with their fabrication.

Integration with Emerging Technologies

As new technologies emerge, castellated mounting holes will adapt to support advanced applications, including those in IoT, 5G, and beyond.

Innovations in Assembly Processes

Ongoing innovations in assembly processes will further simplify the integration of castellated holes into PCB designs, enhancing their appeal in various applications.

Material Advancements

Advances in materials used for PCBs and components will improve the durability and performance of castellated mounting holes, making them even more reliable in demanding applications.

Conclusion

In conclusion, Castellated mounting holes play a crucial role in modern PCB design, offering numerous benefits such as space-saving, simplified assembly, and improved electrical connections. Despite some disadvantages, their versatility and reliability make them indispensable in a wide range of applications, from IoT devices to consumer electronics. As technology continues to evolve, castellated mounting holes will remain a valuable component in the ever-advancing landscape of electronic hardware design.