Temperature Sensor: Types, Design, Benefits & Uses

Introduction

Temperature sensors are indispensable devices used across various industries to measure and monitor temperature changes accurately. From maintaining optimal conditions in HVAC systems to ensuring food safety and controlling industrial processes, temperature sensors play a pivotal role in enhancing efficiency and productivity. This guide explores their functionality, applications, and components.

What are Temperature Sensors?

Temperature sensors are electronic devices used to measure and monitor temperature levels in various applications. They are designed to detect and convert temperature variations into electrical signals that can be easily interpreted and analyzed. These sensors play an important role in numerous industries and are widely used in both residential and commercial settings.

What do Temperature Sensors do?

Temperature sensors measure the thermal conditions of their surroundings by detecting changes in temperature. They provide real-time data on temperature variations, which is crucial for a wide range of applications in various industries, consumer electronics, environmental monitoring, and scientific research.

Uses of Temperature Sensors

Temperature sensors are essential devices that are used in a wide range of applications across various industries. Let’s explore some of the key uses of temperature sensors and how they contribute to our daily lives.

- HVAC Systems: One of the primary uses of temperature sensors is in heating, ventilation, and air conditioning (HVAC) systems. These sensors help to regulate and maintain the desired temperature in homes, offices, and other buildings. By accurately measuring the temperature, the sensors provide valuable data that allows the HVAC system to adjust the heating or cooling output accordingly. This not only ensures comfort but also helps to save energy and reduce utility costs.

- Industrial Processes: Temperature sensors are widely used in various industrial processes to monitor and control temperature. For example, in manufacturing industries, temperature sensors are employed to ensure that equipment and machinery operate within their specified temperature ranges. This helps to prevent overheating, which can lead to equipment failure and production downtime.

- Food Safety and Storage: In refrigeration systems, temperature sensors are used to monitor the temperature of perishable goods, such as meat, dairy products, and vaccines. By maintaining the proper temperature, these sensors help to prevent spoilage and ensure that the products remain safe for consumption or use. Temperature sensors also play a role in food processing, where accurate temperature control is necessary for cooking, baking, and other food preparation processes.

- Environmental Monitoring: Temperature sensors are employed in environmental monitoring systems to collect data on temperature changes in various settings. These sensors are used in weather stations to measure and record outdoor temperatures, which are essential for weather forecasting and climate studies. They are also used in environmental research to monitor temperature fluctuations in ecosystems, bodies of water, and other natural environments. By providing accurate temperature data, these sensors contribute to our understanding of climate change and its impact on the environment.

- Medical Applications: Temperature sensors are widely used in medical applications for monitoring body temperature and controlling temperature in medical devices. In hospitals, temperature sensors are used in patient monitoring systems to measure body temperature and detect fever or hypothermia. These sensors are also used in medical equipment such as incubators, anesthesia machines, and blood storage units to maintain the desired temperature for patient care and the safe storage of medical supplies.

Working of Temperature Sensors

Temperature sensors typically work by measuring the voltage across certain parts like a diode. When temperature increases, the voltage also increases, and this change in voltage between different parts of the diode can tell us the temperature.

The change in temperature is detected by the vibrating wire sensor and converted into an electrical signal, which is then transmitted as a frequency to the read-out unit. The frequency of the signal is directly proportional to the tension (represented by ‘σ’) in the wire.

The formula to describe the relationship between frequency and temperature is as follows:

f = 1/2 * [σg/ρ] / 2L (Hz)

Where:

σ = tension of the wire

ρ = density of the wire

L = length of wire

g = acceleration due to gravity

This formula helps us understand how tight the wire is vibrating, which gives us information about the temperature.

Temperature Sensor Circuit

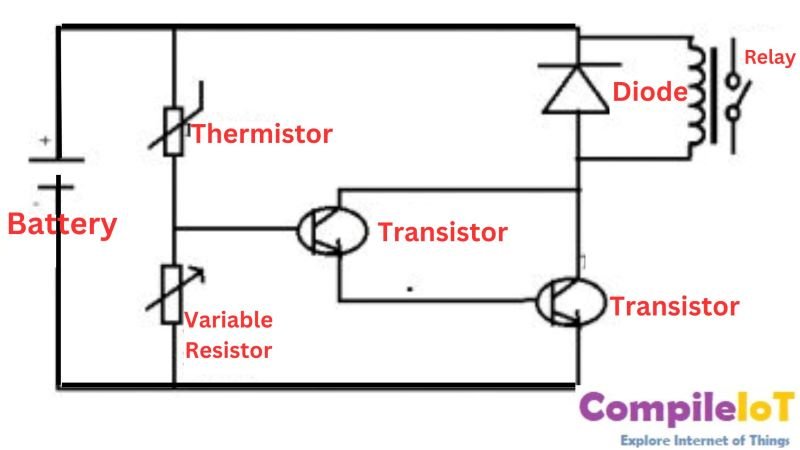

This circuit uses a temperature sensor to control a relay switch. When the temperature reaches a certain level, the relay turns on, allowing power to flow to a connected device. You can use different voltages with this relay, like 110V AC or 220V AC, or even DC appliances. It’s a simple and affordable circuit, perfect for beginners in electronics.

You’ll need a few components: a 9V DC power supply, a 10KΩ thermistor (which senses temperature), a BC547B transistor, a 6V relay, a 1N4007 diode, and a 20KΩ variable resistor. You can power the circuit with a 9V battery, adapter, or transformer.

The circuit uses two BC547B transistors arranged like a Darlington pair, which makes it more sensitive and increases its effectiveness.

You can adjust the temperature range at which the relay activates by using the variable resistor. When the thermistor detects heat, its resistance decreases, allowing current to flow through the transistors.

Once both transistors are activated, they allow voltage to reach the relay, which then switches on. This activates the device connected to the relay, such as a fan. It’s useful for controlling temperature-sensitive equipment or triggering alarms in case of overheating emergencies

Components of Temperature Sensors

Temperature sensors are essential components used in various industries and applications to measure and monitor temperature changes. These sensors play a crucial role in maintaining optimal conditions, ensuring safety, and improving efficiency. In this article, we will explore the different components that make up temperature sensors and how they work.

1. Sensing Element

The sensing element is the core component of a temperature sensor that directly interacts with the environment to measure temperature. There are several types of sensing elements used in temperature sensors, including:

Thermocouples

Thermocouples consist of two different metal wires joined together at one end. When exposed to temperature changes, they generate a voltage proportional to the temperature difference between the measurement point and the reference point. Thermocouples are widely used due to their durability, wide temperature range, and fast response time.

Resistance Temperature Detectors (RTDs)

RTDs are temperature sensors that utilize the principle of electrical resistance. They are made of pure metals, such as platinum, and their resistance changes with temperature. RTDs offer high accuracy and stability over a wide temperature range, making them suitable for precise temperature measurements.

Thermistors

Thermistors are temperature-sensitive resistors made of ceramic or polymer materials. They exhibit a large change in resistance with temperature, allowing for accurate temperature measurements. Thermistors are commonly used in applications where high sensitivity and fast response time are required.

Infrared Sensors

Infrared sensors, also known as pyrometers, measure temperature by detecting the thermal radiation emitted by an object. They are non-contact sensors that can measure temperature from a distance. Infrared sensors are widely used in industrial processes, medical applications, and home appliances.

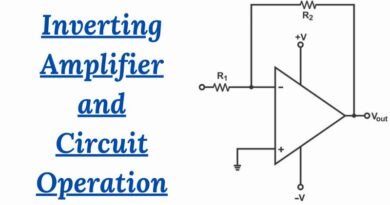

2. Signal Conditioning Circuitry

The signal conditioning circuitry is responsible for processing the output signal from the sensing element and converting it into a usable form. This circuitry ensures that the temperature measurement is accurate and reliable. The signal conditioning circuitry may include:

Amplifiers

Amplifiers are used to amplify the weak electrical signal generated by the sensing element. They increase the signal strength, making it easier to measure and interpret the temperature.

Filters

Filters are used to remove any unwanted noise or interference from the signal. They ensure that the temperature measurement is not affected by external factors and remains accurate.

Analog-to-Digital Converters (ADCs)

ADCs convert the analog signal from the sensing element into a digital signal that can be processed by a microcontroller or computer. This digital signal can then be used for further analysis, storage, or display.

3. Output Interface

The output interface is responsible for presenting the temperature measurement in a user-friendly format. It allows users to easily interpret and utilize the temperature data. Common types of output interfaces include:

Display Screens

Temperature sensors often have built-in display screens that show the measured temperature. These screens can be simple numeric displays or more advanced graphical displays, depending on the application.

Communication Protocols

Many temperature sensors offer communication capabilities to transmit the temperature data to other devices or systems. This can be done through protocols such as UART, I2C, SPI, or wireless protocols like Bluetooth or Wi-Fi. Communication interfaces enable remote monitoring and integration with other systems.

Output Signals

Temperature sensors can also provide output signals in the form of voltage, current, or frequency. These signals can be directly connected to other devices or used for control purposes.

Types of Temperature Sensor

Let’s explore some common types of temperature sensor:

1. Thermocouples

Thermocouples are one of the most commonly used temperature sensors due to their simplicity, low cost, and wide temperature range. They consist of two dissimilar metal wires joined at one end, creating a junction. When the junction is exposed to a temperature gradient, it generates a voltage proportional to the temperature difference. Thermocouples are widely used in industrial applications, such as heating, ventilation, and air conditioning (HVAC) systems, automotive, and manufacturing processes.

2. Resistance Temperature Detectors (RTDs)

RTDs are temperature sensors that utilize the principle of electrical resistance to measure temperature. They are made of a pure metal, such as platinum, nickel, or copper, with a known resistance-temperature relationship. As the temperature changes, the resistance of the metal changes proportionally. RTDs offer high accuracy, stability, and repeatability, making them suitable for precise temperature measurements in industries like pharmaceuticals, food processing, and scientific research.

3. Thermistors

Thermistors are temperature sensors that use the change in electrical resistance with temperature to measure temperature. They are made of semiconductor materials with a negative temperature coefficient (NTC) or positive temperature coefficient (PTC). NTC thermistors have a decreasing resistance with increasing temperature, while PTC thermistors have an increasing resistance. Thermistors are commonly used in consumer electronics, medical devices, and automotive applications.

4. Infrared (IR) Sensors

Infrared sensors, also known as non-contact temperature sensors, measure temperature without physically touching the object or environment. They detect and measure the thermal radiation emitted by the object and convert it into temperature readings. Infrared sensors are widely used in applications where contact-based temperature measurement is not feasible or desirable, such as in medical thermometers, industrial processes, and home automation systems.

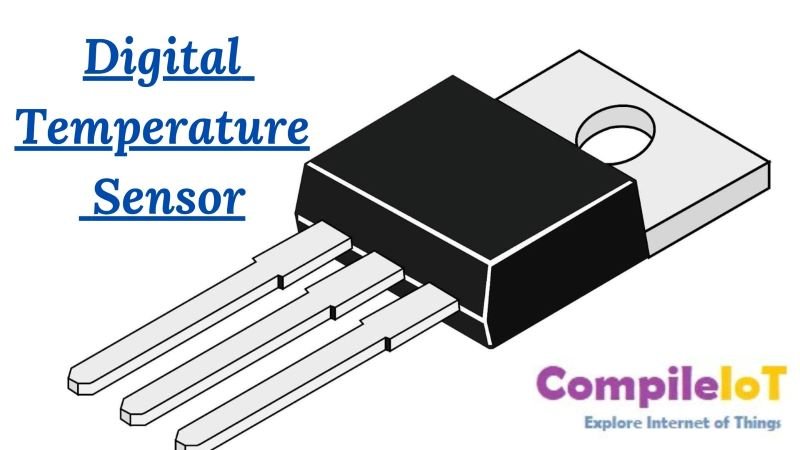

5. Semiconductor Temperature Sensors

Semiconductor temperature sensors are also known as integrated circuit (IC) temperature sensors. They are small, compact devices that use the temperature-dependent voltage or current characteristics of a semiconductor material to measure temperature. They are integrated into electronic circuits and offer high accuracy, linearity, and stability. Semiconductor temperature sensors find applications in consumer electronics, automotive, and industrial automation.

Conclusion

In this guide, we’ve explored temperature sensors, their applications, and components. These electronic devices detect temperature changes, crucial for industries like HVAC, manufacturing, and healthcare. We’ve also examined a temperature sensor circuit, offering a simple solution for temperature control. Temperature sensors are essential tools driving efficiency and innovation across diverse sectors.